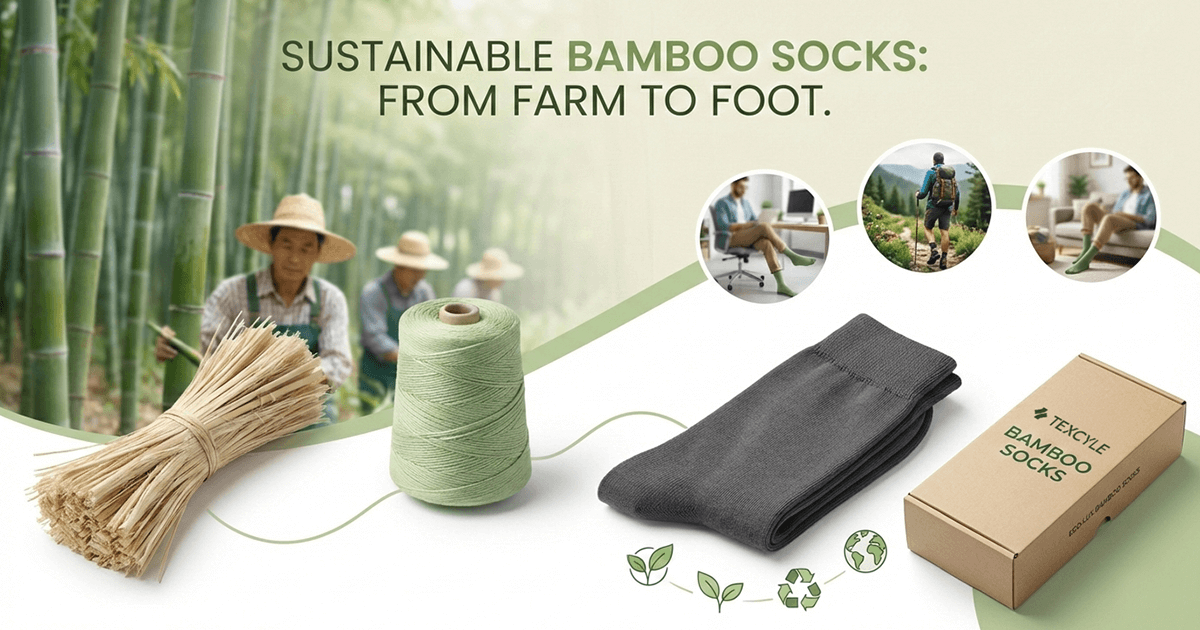

We always emphasise our materials and ethical sourcing, but if sustainable materials aren’t treated sustainably in socks production, can we truly call them sustainable cotton socks? At Texcyle, we don’t just make “better socks”; we make them in a better way.

The fashion industry’s environmental impact is staggering. The Ellen MacArthur Foundation reports that the fashion industry is responsible for 10% of global carbon emissions and 20% of wastewater. Shockingly, a garbage truck full of textiles is landfilled or incinerated every single second. These toxic practices pollute our air and water, deplete resources, and contribute to climate change.

How do we bring about change? Let’s find out with Texcyle.

Lean Philosophy: The Root of Sustainability

Lean manufacturing is a philosophy that focuses on eliminating waste and maximising efficiency throughout the production process. Texcyle has embraced this approach, resulting in a streamlined and sustainable operation. By identifying and eliminating non-value-added activities, Texcyle,the wholesale sock vendor ensures that every step in the production process contributes to creating high-quality, eco-friendly sustainable cotton socks.

The Lean Cycle in Action at Texcyle to Make Sustainable Cotton Socks

Texcyle follows the five key steps of the lean cycle:

- Identify Value: Texcyle clearly defines what constitutes value for its customers – high-quality, sustainable cotton socks that meet specific needs. By understanding customer preferences, they can focus on activities that directly contribute to this value.

- Map the Value Stream: Texcyle meticulously maps out the entire production process, from raw material sourcing to the finished product. This helps identify any bottlenecks or inefficiencies that hinder production flow.

- Create and Maintain Flow: Texcyle implements a smooth and continuous production flow by optimising layout, equipment, and workflow. This minimises waste, reduces lead times, and ensures a consistent supply of products.

- Establish Pull: Texcyle operates on a pull system, producing socks based on actual customer demand rather than relying on forecasts. This prevents overproduction and reduces the risk of inventory buildup.

- Continuous Improvement: Texcyle fosters a culture of continuous improvement, encouraging employees to identify and implement waste reduction opportunities. Regular reviews and data analysis help refine processes and maintain efficiency.

Benefits of Lean Manufacturing for Sustainability and Retailers

As a wholesale Cotton sock vendor,Texcyle understands that simply claiming to be “green” isn’t enough if it doesn’t add value for consumers. Here are some benefits of lean manufacturing practices that can make a significant difference for UK retailers:

Benefits for Sustainability

- Reduced Waste & Resource Consumption:

Texcyle minimises fabric waste during cutting and customization by applying lean principles, which focus on eliminating various types of waste. MindTools reports that lean manufacturing can reduce waste by up to 30%. - Just-in-Time (JIT) Inventory Management:

By using a JIT inventory system, Texcyle produces based on confirmed orders, avoiding overproduction and reducing the environmental impact of excess material storage. Lean practices can lead to inventory reductions of 20-50% according to MindTools. - Lower Carbon Footprint:

Optimising production processes and reducing waste significantly lower Texcyle’s carbon footprint. The Environmental Protection Agency (EPA) reports that lean principles can achieve energy reductions of 15-25%. Texcyle aims to be carbon neutral within a few years. - Sustainable Supply Chains:

Lean manufacturing fosters collaboration with suppliers to adopt sustainable practices, creating a more resilient and eco-friendly supply chain. The World Business Council for Sustainable Development found that 70% of companies with strong sustainability programs implement lean principles. Texcyle seeks sustainable cotton socks retailers in the UK to promote these practices to eco-conscious consumers. - Energy Efficiency:

Texcyle prioritises energy-efficient machinery, utilises natural light, and explores renewable energy options to further reduce their carbon footprint. - Employee Empowerment:

Texcyle’s lean philosophy encourages employee involvement in problem-solving and process improvement, fostering a culture of innovation and sustainability.

Benefits for Retailers

Lean manufacturing not only benefits the planet but also offers unique advantages to retailers, enhancing business performance and brand image.

- Enhanced Efficiency and Productivity:

Lean manufacturing leads to faster production times, reduced lead times, and improved order fulfilment. McKinsey & Company found that companies implementing lean principles experience an average productivity increase of 20-30%.Retailers in the UK who partner with Texcyle will never miss the opportunity to deliver sustainable cotton socks to their customers on time. - Cost Reduction:

By eliminating waste and optimising processes, Texcyle helps retailers enjoy lower production costs and better profit margins. The Lean Enterprise Research Center reports that lean initiatives can lead to cost reductions of 10-15%. - Improved Quality:

Texcyle’s lean manufacturing emphasises continuous improvement, resulting in higher product quality and reduced returns. The American Society for Quality found that companies with mature lean programs experienced a 30-50% reduction in defects. - Increased Flexibility:

Lean operations enable retailers to adapt to changing market demands more quickly. Partnering with Texcyle ensures that you can meet customer needs effectively. - Stronger Brand Image:

Retailers adopting lean manufacturing practices can position themselves as environmentally conscious and socially responsible, attracting eco-conscious consumers. Nielsen found that 66% of global consumers are willing to pay more for products from companies committed to sustainability.So, your brand building will be easier with Texcyle.

Texcyle is committed to implementing a circular economy, utilising recycled materials such as polyester from plastic bottles. Our goal is to turn every step of the process green , from ethical sourcing to closing the loop at the end of the product life cycle. We don’t just claim sustainability; we live it. If you want to join this seamless system of delivering sustainable cotton socks for the benefit of your business and the environment, you’re in the right place. Connect with the leading wholesale sock vendor, Texcyle for the change that both the world and consumers need.