Let’s start with a shocking reality—In January and February 2025, over 1,300 dead Olive Ridley turtles were found along the Tamil Nadu coast,India. These turtles are believed to have drowned after becoming entangled in fishing nets. Unfortunately, such tragic incidents are not new and as a sustainable sock vendor it puts us in pain. Fishing nets are not just trapping fish; they are ensnaring marine biodiversity and suffocating entire ecosystems.

So, how do we mitigate this problem? Stopping fishing altogether isn’t a viable solution. Instead, we need an approach that balances environmental conservation with economic viability. The answer lies in the circular economy—giving discarded fishing nets a second life while simultaneously addressing the fashion industry’s carbon footprint.

Why Recycling Is The Only Choice Left

Imagine diving into the ocean and being greeted not by colorful fish but by abandoned fishing nets swaying like ghostly traps beneath the waves. Every year, around 6.4 million tons of fishing gear are lost at sea, with over 0.45 million tons becoming deadly marine pollution. These so-called “ghost nets” don’t just disappear—they continue drifting in the ocean, trapping fish, sea turtles, and other marine life for decades, even centuries.

Recycling fishing nets into nylon may not completely eliminate the problem, but it presents a powerful solution that significantly reduces marine pollution while creating high-quality, sustainable textiles.

What is Nylon?

Nylon is a synthetic polymer belonging to the polyamide family, known for its durability, stretchability, and versatility. Originally developed as an alternative to silk, nylon quickly became a staple in activewear, swimwear, hosiery, and performance garments. However, its production is highly resource-intensive and relies on fossil fuels, making it a significant contributor to carbon emissions and plastic pollution.

Virgin Nylon vs. Recycled Nylon: The Carbon Footprint Factor

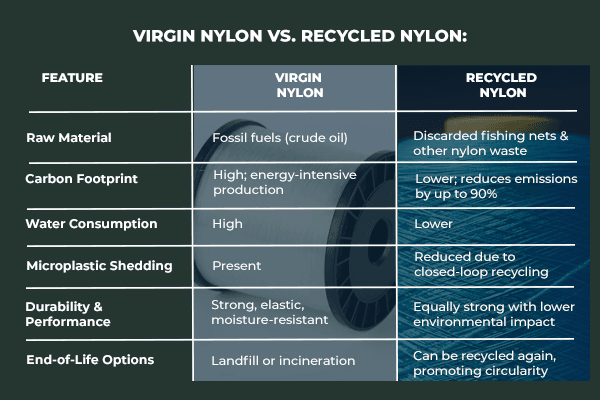

The production of virgin nylon is energy-intensive, requiring crude oil and generating substantial greenhouse gas emissions. Additionally, it sheds microplastic fibers during manufacturing and use, further polluting the environment. Once disposed of, nylon garments persist in landfills for centuries unless alternative recycling solutions are implemented.

On the other hand, recycled nylon retains the same texture and utility as virgin nylon but offers a far more sustainable alternative. Recycled nylon, particularly from discarded fishing nets, provides a circular solution to marine pollution and textile waste. By repurposing waste materials, it reduces the reliance on virgin resources, cutting down carbon emissions and energy consumption. Moreover, recycling fishing nets prevents them from harming marine ecosystems and gives them a second life in fashion.

Why Fishing Nets are the Best Choice for Recycled Nylon

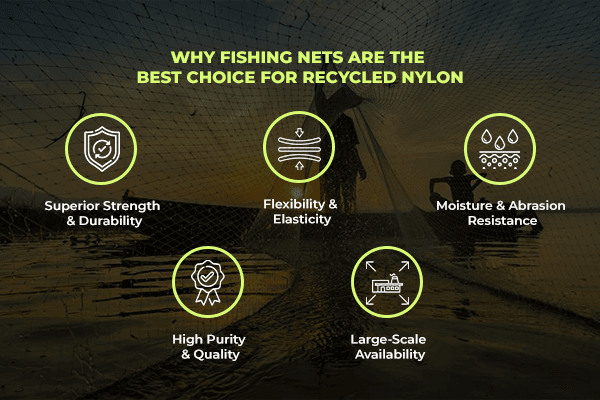

Not all plastic waste is suitable for textile production, but fishing nets are among the best sources for recycled nylon due to their exceptional material properties. Here’s why:

- Superior Strength & Durability: Fishing nets are made from high-quality nylon engineered to withstand harsh marine environments. This makes them ideal for repurposing into durable, high-performance fabrics.

- Flexibility & Elasticity: The polyamide-based structure of fishing nets allows the resulting recycled nylon to retain the stretch and resilience needed for textiles, particularly in sportswear and socks.

- Moisture & Abrasion Resistance: Fishing nets are designed to resist water exposure, UV rays, and rough conditions, making their recycled fibers perfect for activewear, swimwear, and performance-oriented clothing.

- High Purity & Quality: Unlike mixed plastic waste, which requires extensive sorting and processing, fishing nets are predominantly made from nylon (polyamide), simplifying the recycling process and ensuring a high-quality final product.

- Large-Scale Availability: With millions of tons of discarded nets polluting our oceans each year, they provide a reliable and abundant raw material for sustainable textile production.

From Waste Nets to Wearable Comfort: How Fishing Nets Become Nylon

Transforming discarded fishing nets into recycled nylon involves a meticulous process:

- Collection: Ghost nets are retrieved from oceans and coastal areas.

- Cleaning & Sorting: The nets are washed to remove debris and sorted by material.

- Shredding & Depolymerization: The nylon is broken down into its raw molecular components.

- Polymerization: The purified material is reassembled into high-quality nylon pellets.

- Fiber Spinning: These pellets are melted and spun into fine, durable nylon yarn.

- Textile Production: This yarn is knitted or woven into fabrics used in clothing, socks, and accessories.

How Nylon Enhances Performance Socks

Nylon plays a key role in sock manufacturing, particularly for athletic, compression, hiking, football socks, and dress socks. It can be blended with organic cotton socks for an enhanced performance. Benefits of nylon in socks include:

- Durability: Extends the lifespan of socks, reducing waste.

- Stretch & Comfort: Ensures a snug fit without sagging.

- Moisture Resistance: Helps wick sweat away, keeping feet dry.

- Athleisure Appeal: Perfect for performance socks in sports and outdoor activities.

- Digital Printability: Allows for high-quality, vibrant prints on socks.

- Abrasion Resistance: Protects against wear and tear, ensuring long-lasting quality.

The Future is Green—In Fashion and Beyond

As a sustainable sock vendor, we are doing our part every single minute. Many times, we have had to use nylon in our socks to make them durable for long wear and sports activities. Even for our digitally printed socks, organic cotton works well, but blending it with nylon delivers the best results. . If it’s essential for both the environment and us, why not do it in a better, more sustainable way? We adhere to ethical and green practices in sustainability.

But Is It Enough?

As a sustainable sock vendor, we are making socks—but as a retailer, you can be part of the change. To solve this plastic problem, we need to popularize recycling and the circular economy by creating more consumers for sustainable products.Several major fashion brands like Adidas, Patagonia, and Levi’s have already started embracing this movement.

Big or small, change is the only constant. Do you want to be part of this movement? Contact Texcyle for bulk custom socks.